The challenge before Johns Hopkins University engineering students: Take a leaf blower, but make it quiet. Make it work as powerfully as ever, but do not allow it to emit the ear-piercing caterwaul that has gotten leaf blowers banned in some communities and cursed in many others.

Shocking their sponsors, their advisers, and even themselves a little, the students did it.

Their improved leaf blower drops the overall noise level by nearly 40% while almost entirely erasing the most obnoxious frequencies. The design is patent-pending and Stanley Black & Decker expects to be selling them in two years.

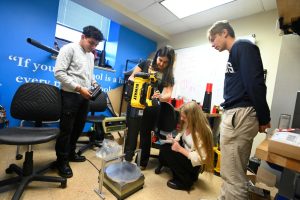

“We spent many hours on this project, just going through the various versions of it, just constantly iterating and improving and so for that to finally pay off, this was really, really rewarding,” said team member Michael Chacon, who like the rest of the four-member team is a senior majoring in mechanical engineering. “We are stoked and super, super proud.”

The team started working last September. They hoped to improve an electric or battery-powered leaf blower, which is already much quieter than the notorious gas-powered ones, where the sound can carry over an average suburban block.

They spent months figuring out the leaf blower piece by piece, analyzing all of its the noises and why it made them. They then spent many more months spit-balling possible improvements, refining some ideas, killing even more.

Video: Aubrey Morse/JHU

“The sound that comes out of this leaf blower is very complicated and it contains a lot of different frequencies,” said team member Andrew Palacio. “A lot of different notes on a piano would be a good analogy.”

They workshopped more than 40 versions of the solution they finally settled on: an attachment that cuts the machine’s noise almost like a silencer on a gun or a muffler on a car.

“Our product takes in a full blow of air and separates it,” said team member Leen Alfaoury. “Some of that air comes out as it is, and part of it comes out shifted. The combination of these two sections of the air makes the blower less noisy.”

Adds Chacon: “It ultimately dampens the sound as it leaves, but it keeps all that force, which is the beauty of it.”

Their design cuts the most shrill and annoying frequencies by about 12 decibels, which all but removes them, making them 94% quieter. The team reduced the overall leaf blower noise by about two decibels, making the machine sound 37% quieter.

So it’s a quieter machine, and what people can hear will sound more pleasant.

So it’s a quieter machine, and what people can hear will sound more pleasant.

“It’s the difference between hearing a high-pitched whistle and hearing what you might think of as wind noise,” said team member Madison Morrison.

Alfaoury thinks the best way to describe it is “muffled.”

“It’s suppressed, if that makes sense,” she said. “Like the noise is deeper. It is not screechy. There’s no high pitch sound that is like really annoying to hear.”

Team adviser Stephen Belkoff puts it bluntly: “It’s still a leaf blower but it’s not nearly as annoying as it was before they got involved.”

The design wowed Stanley Black & Decker officials, who can’t wait to start manufacturing and selling the new tools.

“It’s not just some cool theoretical thing that will sit on a shelf and never be heard from again—this is ready to be mass manufactured,” said Nate Greene, senior product manager at Stanley Black & Decker, who graduated from Johns Hopkins in 2017 with an engineering degree. “This is a really rare and dramatic level of success.”

The student team expects their solution could be adapted to quiet other similarly loud appliances like vacuums and hairdryers.