The temperature chamber is completely independent of the mechanical testing. This means that you cannot trigger a temperature variation by a mechanical signal. This also means that the software is NOT recording the temperature during a test. What you can do is time the temperature program according to your mechanical test.

If you want to do a test at constant temperature

1. Create a variable in your method called Temperature in panel input and make sure to document the temperature of the test.

2. Place the specimen in the chamber.

3. Set the target temperature using the arrows on the temperature controller

4. Close the chamber. There is a safety in the chamber door that prevents the chamber to try to reach the target temperature if the door is not fully closed.

5. Once the temperature equilibrates, open the door just enough to reach the specimen, leave the specimen as much as possible inside, and measure the dimensions of the specimen at the target temperature. WEAR the right protective equipment for the temperature you are reaching. If you touch very cold pieces of metal, such as the grips or the pull rods, your skin will stick to them.

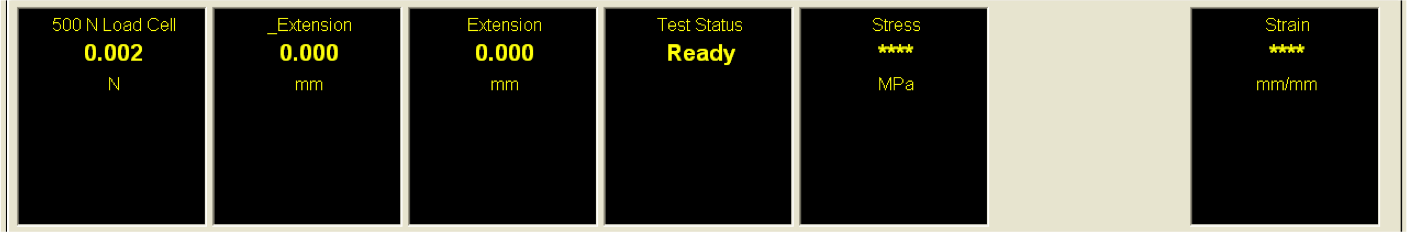

6. Place the specimen in the grips. Zero the _Extension and load channels: Right click on the corresponding Meter (see picture) and select Zero channel.

7. Close the door and wait for the chamber to go back to the right temperature. Make sure the load stays at zero during that time. Use the manual commands if necessary to move the crosshead up or down.

7. Close the door and wait for the chamber to go back to the right temperature. Make sure the load stays at zero during that time. Use the manual commands if necessary to move the crosshead up or down.

8. In the mean time, input the specimen dimensions in the software and prepare the test.

9. Start the test.

10. If you are testing at low temperatures,

At the end of the test, crack open the door and wait for one or two minutes for the nitrogen in the chamber to leave slowly. This will prevent the operator from getting a blow of nitrogen opening the door and being short of breath for a couple of seconds. Use cryogloves to touch the grips and the specimen.

10. If you are testing at high temperatures, At the end of the test, fully open the door and wait for one or two minutes for the temperature in the chamber to decrease. Use gloves to touch the grips and the specimen.

If you want to change temperature during the test.

1. You need to program either a temperature program or temperature set points directly into the temperature controller. Use the controller manual to do so. It is tricky.

2. Make sure you time your changes properly and leave a lot of margin time for the temperature to reach a stabilized value before the mechanical testing.

3. During the temperature changes, make sure that the method in TestWorks corresponds to either zero load if you want to adapt to the change in length or hold the strain if you want to measure the change in load. A zero load segment will need PID parameters corresponding to our material. Go to the help of the software to figure out how to set up PID parameters. From our experience with very soft elastomers, the PID regulation of the machine is very weak.

Note: from what I know of the system, it might be simpler and more efficient to actually prepare three methods, for before, during, and after the temperature change. You can then manually go from one to the other and change the temperature on the controller. You will have small breaks in between tests, so time management might be an issue.

4. See instructions above (#10) for the end of the test precautions.